Wind Turbine Power Coefficient

Wind energy is becoming more popular all around the world. Wind energy is expected to account for one-third of worldwide power supply by 2050. This is fueling advancements in blade and equipment design. Engineers are constantly looking for new ways to improve the aerodynamic properties of blades. In addition, tip speeds should be increased.

Wind turbines, on the other hand, have a lifespan of 15 years or more. Repair and maintenance expenditures may steadily rise throughout this time owing to wear and tear. Also, older equipment may be unable to keep up with modern turbines.

New locations are difficult to find and expensive to establish. As a result, wind turbine retrofitting is an appealing investment for wind farm operators. It does not have to be a complete redesign. Even minor power curve improvements can result in yearly energy output gains of 2-4%. Depending on the turbine design, local energy rates, and wind dispersion, the return on investment is generally 1-3 years.

Downtime, as well as operational and maintenance expenditures, must be minimised by wind farm operators. All the while, keeping an eye on the wind turbine power curve charts to maximise annual energy output. Renewable energy has a massive environmental impact. That is why we are committed to assisting businesses in meeting the constant difficulties of optimising their sites through retrofits and upkeep.

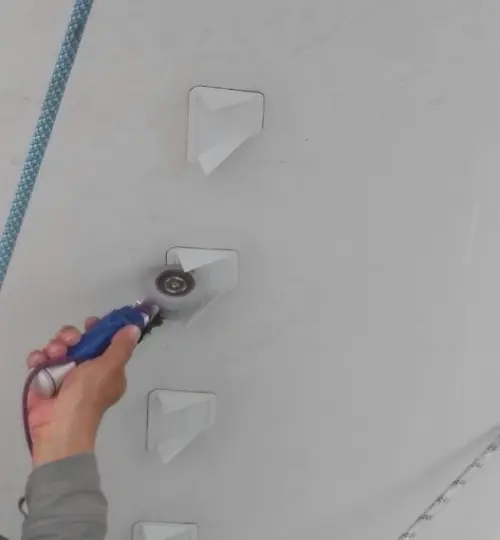

Dangle Wind Turbines is a wind turbine installation firm that specialises in wind turbine blade retrofits. We can assist you in optimising the design of wind turbine blades. Installing vortex generators, gurney flaps, and other aerodynamic enhancements, for example. These methods have the potential to minimise draught while increasing lift. As a result, your wind turbine will produce power more efficiently. And increase the power coefficient of your wind turbine.

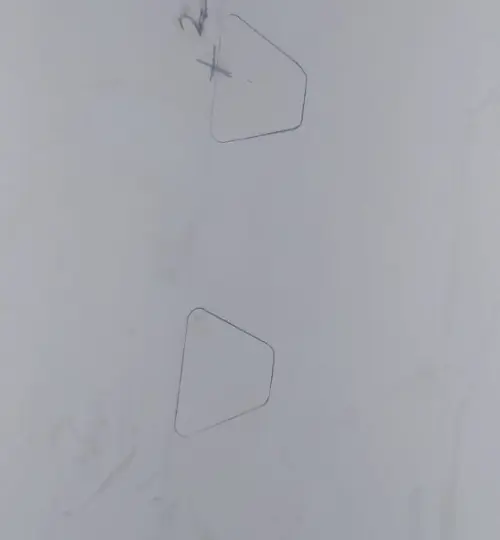

Vortex generators are affixed to a turbine blade's root portion. These can assist to minimise flow separation and improve overall turbine performance. They have been demonstrated to extend service life as well as power and load.

We can provide a full service thanks to an innovative collaboration with Power Curve ApS. It includes specialised design and testing, adaptable access options, and skilled installation. We can contribute cutting-edge technical understanding and modeling, as well as installation expertise.

For selected turbine types, our service includes a design warranty. And a co-financing offer for 2020 installations. This technology is already in use at over 700 locations. This reduces your project risk across a variety of turbine brands.

AeroPower is an award-winning, family-run company with global expertise. Because of our size and structure, we can always provide a flexible and varied approach. We commit to the greatest levels of safety, quality, and service. We are excited to launch this useful new service thanks to unique collaborations. In addition, to contribute to the growth of the INDIA wind farm sector. We will work smoothly with your staff to provide a smooth and efficient installation procedure.